There are several special features and markings on steel rulers designed to aid in precise measurements or specific applications. Some of these include:

Non-glare Finish: The non-glare finish on steel rulers is achieved through various surface treatments aimed at diffusing light and reducing reflections. Common methods include bead blasting, chemical etching, or applying a specialized coating. By minimizing glare and reflections, this finish ensures optimal visibility of measurement markings, even under intense lighting conditions such as direct sunlight or harsh indoor lighting. It enhances user comfort and accuracy by reducing eye strain and eliminating potential errors caused by obscured or distorted readings due to glare.

Raised Markings: Unlike traditional printed markings, raised or embossed markings on steel rulers are produced through a process that physically alters the ruler's surface. This method typically involves stamping or machining the markings to create raised ridges or depressions on the ruler. The resulting raised markings offer superior durability and longevity compared to printed counterparts, as they are less susceptible to wear, fading, or smudging over time. The tactile nature of raised markings provides tactile feedback to users, aiding in precise measurement placement and reducing the likelihood of errors, particularly in environments where visibility may be compromised.

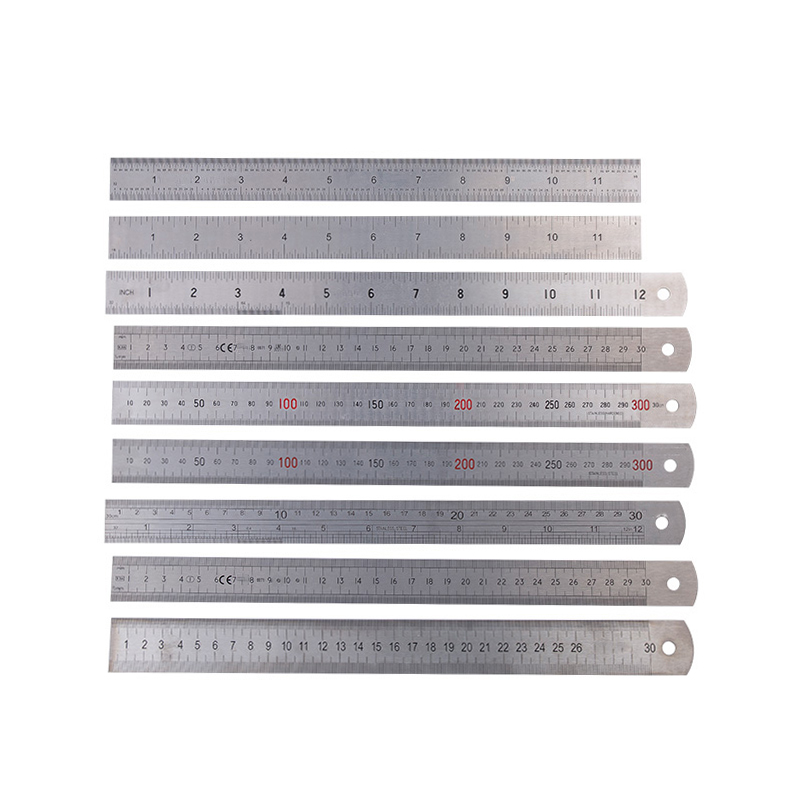

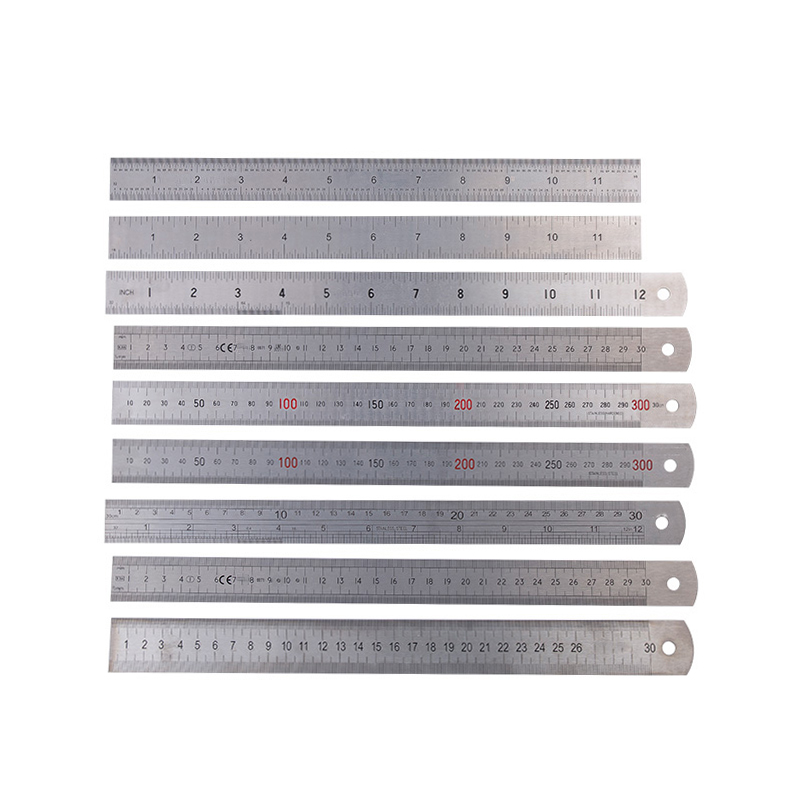

Conversions: Steel rulers with conversion tables or scales offer invaluable versatility by facilitating seamless transitions between different units of measurement. These rulers may feature dual scales, displaying both imperial and metric measurements side by side or on opposite sides of the ruler. In addition to basic unit conversions, some rulers incorporate specialized conversion tables for specific applications, such as converting linear measurements to area or volume equivalents. This feature streamlines measurement tasks by eliminating the need for manual calculations or reference to external conversion charts, thereby saving time and reducing the risk of errors associated with manual conversions.

Center Finding Scales: Center finding scales on steel rulers are designed to simplify the process of locating the center point of a measurement. These scales typically consist of evenly spaced graduations extending from both edges of the ruler towards the center. By aligning measurements from opposing edges, users can quickly and accurately identify the midpoint of a linear measurement without the need for additional tools or calculations. This feature is particularly beneficial in applications requiring precise centering, such as layout work, machining setups, or dividing materials for fabrication or assembly.

End Graduations: Steel rulers with end graduations extend their measurement capabilities beyond the main scale by incorporating additional graduations at the ruler's ends. These graduations are positioned close to the ruler's edge, allowing users to make accurate measurements of small distances directly from the edge of the ruler. End graduations are especially useful for tasks requiring fine measurement adjustments or incremental measurements in confined spaces where traditional scale markings may be obscured or difficult to read. By providing convenient reference points at the ruler's extremities, end graduations enhance measurement accuracy and efficiency, particularly in precision-critical applications such as model making, jewelry crafting, or electronic assembly.

Can produce from 100mm to 2000mm

Can supply different width and thickness for each size

High visibility etched markings

Different graduations for your choose

[email protected] / [email protected]

[email protected] / [email protected]

+86-571-81993095

+86-571-81993095