Certainly! Here are some tips and techniques for using a combination square more effectively:

1.Ensure squareness: Before using the combination square, check its squareness by aligning the blade with an edge or surface known to be square. This will help you verify its accuracy.

2.Clean and maintain the square: Keep the combination square clean and free from debris that could affect its accuracy. Regularly wipe it down and store it in a protective case to prevent damage.

3.Secure the locking mechanism: When setting the desired measurement, make sure to lock the blade securely in place using the locking mechanism. This will prevent any unintentional movement while measuring or marking.

4.Use the scriber carefully: The scriber is the pointed end of the blade used for marking. Apply light pressure and use a controlled motion to make precise marks on the material. Avoid excessive force, as it may damage the surface or affect accuracy.

5.Utilize the spirit level: Many combination squares have a built-in spirit level. Take advantage of this feature to ensure level or plumb measurements. Adjust the workpiece or square as needed to achieve a level position.

6.Support the workpiece: When measuring or marking on a large or unstable workpiece, use additional supports or clamps to stabilize it. This will help maintain accuracy and prevent any movement during the process.

7.Double-check measurements: For critical or precise tasks, it's a good practice to double-check your measurements using different reference points or techniques. This helps ensure accuracy and minimize errors.

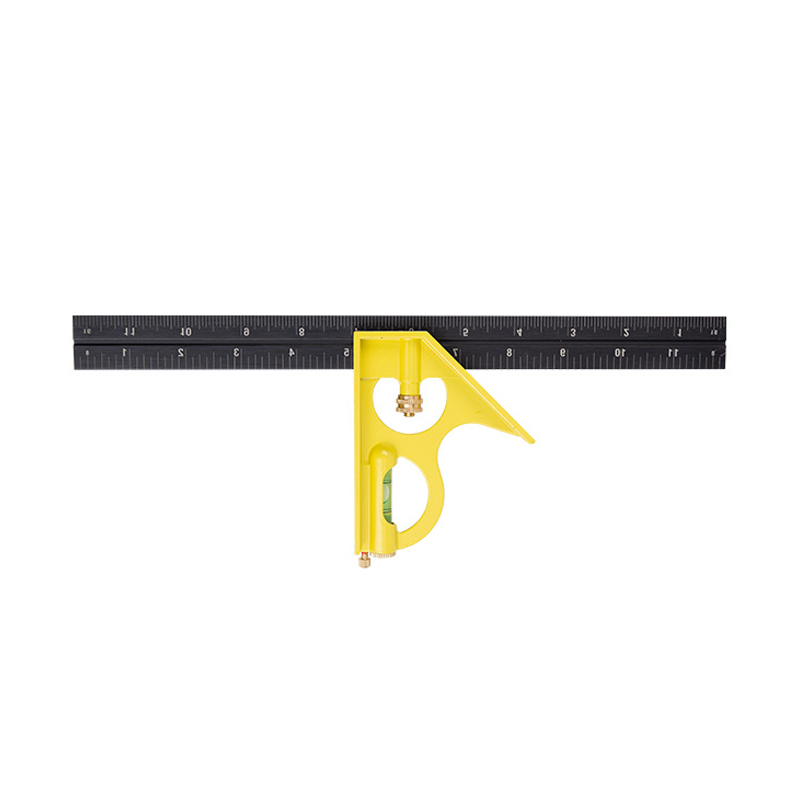

Zinc handle combination square

1. CNC machined zinc head for guaranteed accuracy.

2. Stainless steel blade with black PVD coating and laser graduations.

3. Brass lock for fast adjustment and secure hold.

4. Scriber pin stored on board for convenient marking of materials.