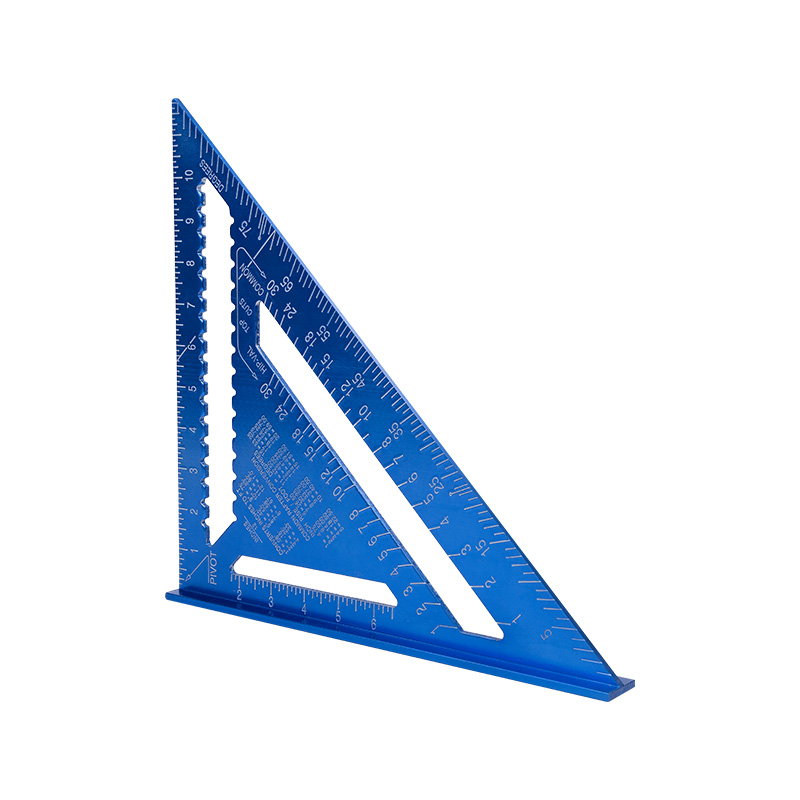

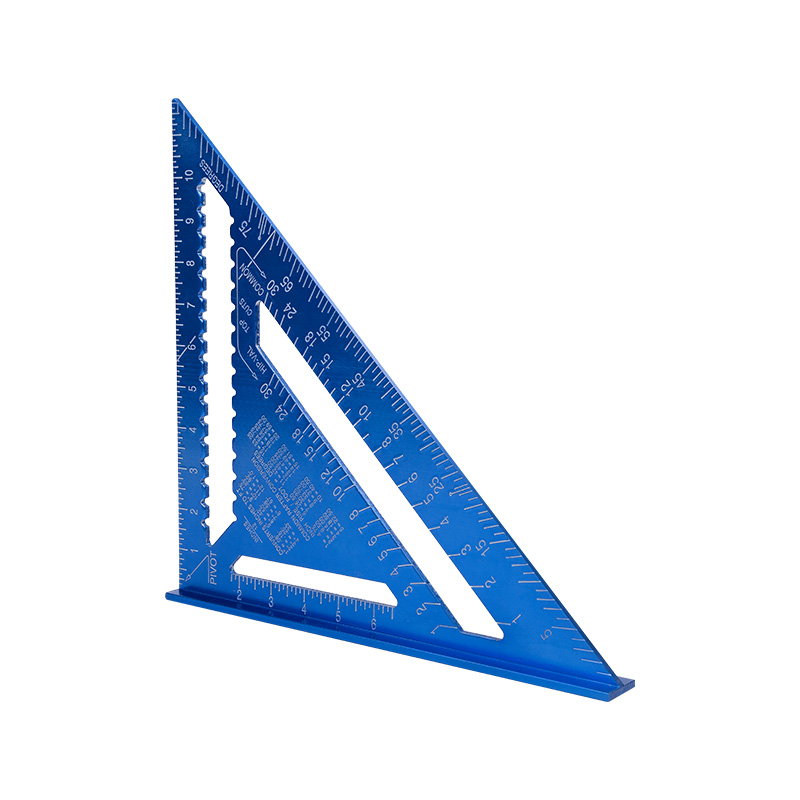

The rafter square, also known as a framing square or carpenter's square, is a versatile tool used in carpentry and construction for measuring and marking angles accurately on various materials including wood, metal, and plastic. Here's how it assists in measuring and marking angles on different materials:

1.Versatility and Material Compatibility:

A rafter square is crafted from durable materials like aluminum, stainless steel, or high-quality plastic. This choice of materials ensures the square's longevity and usability across a wide range of materials, including wood, metal, and plastic. Its robust construction allows it to withstand the pressures of professional construction environments.

2.Precision Measurements:

The rafter square is meticulously calibrated with accurate markings and numbers. These engravings are essential for precise measurements. Carpenters and craftsmen rely on these markings to ensure accuracy when measuring and marking angles. This precision is vital, especially in tasks where even a slight deviation can result in ill-fitting joints or inaccurate cuts.

3.Right Angle Reference:

The rafter square's inherent 90-degree angle serves as an indispensable reference point. Carpenters use this feature to confirm the squareness of corners and joints. In professional settings, maintaining perfect right angles is fundamental to the structural integrity and aesthetic appeal of finished products.

4.Angle Guides and Adjustability:

The degree markings along the edges of the rafter square enable professionals to measure and mark angles with exceptional accuracy. Additionally, the adjustable arm feature allows craftsmen to set and mark a variety of angles quickly and precisely. This flexibility is crucial in complex construction projects, especially those involving roof framing, where angles can vary significantly.

5.Scribing Lines:

A fundamental aspect of carpentry involves scribing lines accurately on materials. The rafter square, with its straight edge and stable base, facilitates this task. Craftsmen press the square firmly against the material and trace along its edge with a pencil or scribing tool. This process results in consistently straight and accurate lines, ensuring precise cuts and alignments during construction.

6.Stability and Ease of Use:

The flat base of the rafter square provides stability when marking angles. This stability is invaluable in professional settings, where efficiency and accuracy are paramount. Craftsmen can confidently mark angles without worrying about the square slipping or shifting, thus ensuring consistent and precise measurements every time.

7.Durability and Longevity:

Professional-grade rafter squares are engineered for durability. They are designed to endure the demands of construction sites, resisting wear and tear. Their corrosion-resistant properties make them ideal for use in various weather conditions, ensuring their longevity and maintaining their accuracy over time.

8.Ease of Use: Rafter squares are easy to handle and manipulate, allowing carpenters to quickly and efficiently measure and mark angles without the need for complex equipment.

The rafter square is an indispensable tool in the toolkit of any professional carpenter or craftsman. Its versatility, precision, stability, and durability make it an essential instrument for accurately measuring and marking angles on a wide array of materials, ensuring the successful completion of high-quality construction and woodworking projects.

Extruded aluminum with blue or black oxidation

High visibility laser Inch or metric graduations

Conversion tables for common application needs

[email protected] / [email protected]

[email protected] / [email protected]

+86-571-81993095

+86-571-81993095