The combination square is an incredibly versatile tool with various applications in both woodworking and metalworking. Here are some primary uses:

Measuring: Within woodworking and metalworking, precise measurements are the foundation of successful projects. A combination square is the go-to tool for craftsmen seeking accuracy in their work. Its finely calibrated ruler, often crafted from durable stainless steel, provides precise measurements in both imperial and metric units. This level of precision allows artisans to mark, cut, and shape materials with confidence, knowing that their measurements are accurate to the millimeter or fraction of an inch.

Marking: The versatility of a combination square extends to marking tasks, where precision is paramount. Woodworkers and metalworkers rely on its adjustable ruler and integrated scribing tool to create crisp and exact markings on various materials. Whether delineating the layout for intricate joinery or marking out the precise locations for drilling or cutting, the combination square ensures that each mark is made with precision and consistency, laying the groundwork for flawless execution.

Checking Squareness: In the realm of woodworking and metalworking, achieving perfect right angles is a fundamental requirement for precision craftsmanship. The combination square serves as an indispensable tool for verifying squareness, ensuring that corners and edges meet at precisely 90-degree angles. Craftsmen use the square's robust construction and accurate measurements to confirm the squareness of workpieces, guaranteeing the integrity of cuts, joints, and assemblies.

Setting Up Machinery: Precision machinery demands meticulous setup to achieve optimal performance and accuracy. In metalworking workshops, combination squares are instrumental in aligning saw blades, drill bits, and other cutting tools with precision. By ensuring that these tools are perfectly perpendicular to the workpiece, craftsmen can achieve clean cuts, accurate bores, and machined surfaces that meet the most exacting standards of quality and precision.

Layout Work: The combination square shines brightest during layout tasks, where accuracy and attention to detail are paramount. Woodworkers rely on its versatility to transfer precise measurements and angles onto their workpieces, guiding the creation of complex joinery and intricate designs. Similarly, metalworkers use combination squares to mark out precise locations for holes, fasteners, and other components, ensuring that each piece of the puzzle fits together seamlessly and precisely.

Creating Angles: From bevels to miters, the ability to cut precise angles is essential in both woodworking and metalworking. The adjustable protractor head of a combination square empowers craftsmen to mark and cut angles with surgical precision. Whether crafting complex joinery or fabricating structural components, artisans trust the combination square to deliver accuracy and consistency, ensuring that each angle is executed flawlessly and fits seamlessly into the larger assembly.

Testing Flatness: In the pursuit of perfection, craftsmen must assess the flatness and alignment of their workpieces with precision. The combination square serves as a versatile tool for this purpose, allowing artisans to detect even the slightest deviations from flatness. By running the square's ruler along a surface, craftsmen can identify imperfections and irregularities, ensuring that each workpiece meets the exacting standards of flatness and surface quality required for a flawless finish.

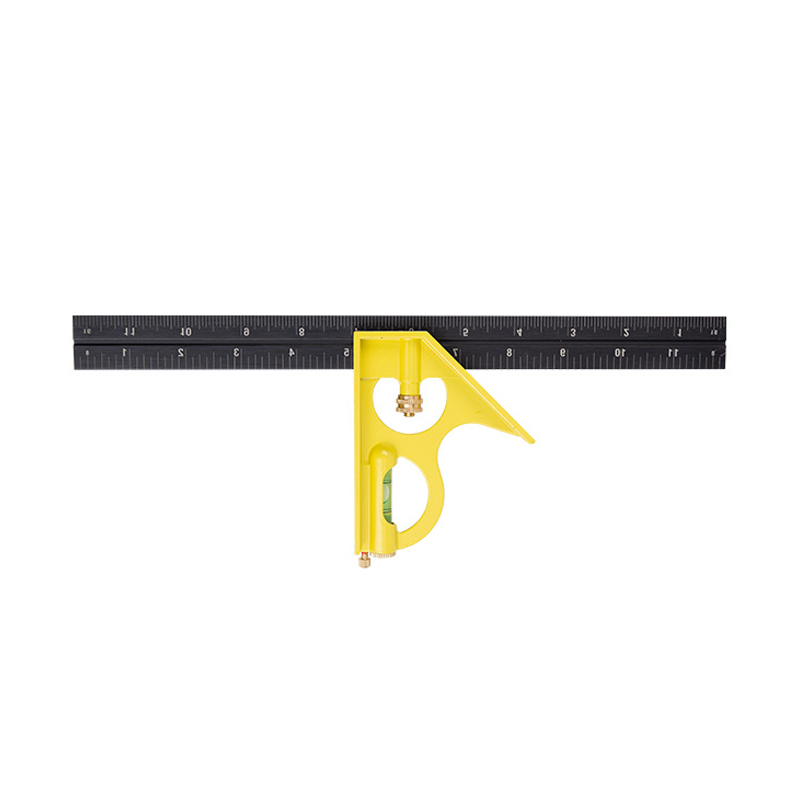

Zinc handle combination square

English

English Español

Español