Importance of the Adjustable Head on a Combination Square

Versatility in Applications: The adjustable head of a combination square significantly enhances its versatility, transforming it into a multifunctional tool. This adaptability allows the square to be used for a variety of tasks beyond basic measurement. For instance, it can be utilized for checking the squareness of joints, marking precise lines for cutting, and measuring angles. The ability to adjust the head along the length of the blade makes it suitable for both small and large projects, offering exceptional flexibility in various applications, whether in woodworking, metalworking, or construction.

Enhanced Precision and Accuracy: Precision is crucial in many professional fields, and the adjustable head of a combination square plays a pivotal role in achieving this. By allowing the user to set the head to exact measurements and angles, the tool helps ensure that each measurement is accurate. The locking mechanism secures the head firmly in place, preventing any movement that could lead to measurement errors. This level of accuracy is particularly important for tasks that demand high precision, such as aligning parts in machinery or setting up frameworks in construction.

Customization for Specific Tasks: The customizable nature of the adjustable head allows the combination square to be tailored to specific tasks. Whether you need to measure a precise length, mark an angle, or check for square, the head can be adjusted and locked to the required position. This customization ability is essential for performing tasks that have unique or variable requirements. For example, when creating angled cuts or checking the alignment of components, the adjustable head provides the flexibility needed to achieve the desired results.

Consistency and Reusability: The ability to lock the adjustable head in place ensures that once a measurement or angle is set, it remains consistent across multiple uses. This feature is particularly useful for repetitive tasks where maintaining uniformity is critical. For instance, in production environments where identical parts need to be cut or assembled, the ability to lock and reuse the same settings helps maintain consistency and quality throughout the process.

How to Accurately Set the Adjustable Head

Prepare the Tool: Before adjusting the head, ensure that both the blade and the head are clean and free from debris. Dirt, dust, or residues on these surfaces can interfere with accurate measurements. Use a soft, lint-free cloth to gently wipe down the components, ensuring a clean working surface.

Align the Head Precisely: Position the adjustable head at the desired measurement or angle on the blade. It is crucial to align the head precisely with the blade to avoid measurement discrepancies. This alignment can be checked using a reference point or a known standard to ensure that the head is correctly positioned. If measuring angles, use the tool's built-in scale or a protractor to achieve the desired angle accurately.

Secure the Head: Once the head is positioned, use the locking mechanism—typically a screw or clamp—to secure it in place. Ensure that the head is tightly fastened to prevent any movement during use. However, be cautious not to over-tighten the mechanism, as excessive force can damage the tool or make future adjustments difficult. Properly securing the head ensures that it remains stationary and maintains accuracy during measurement and marking.

Verify Measurement Accuracy: After setting and locking the head, verify the accuracy of the measurement or angle using a reliable reference tool. This verification step helps confirm that the head is correctly positioned and that the measurements are precise. Compare the settings with a known accurate tool or standard to ensure that there are no discrepancies.

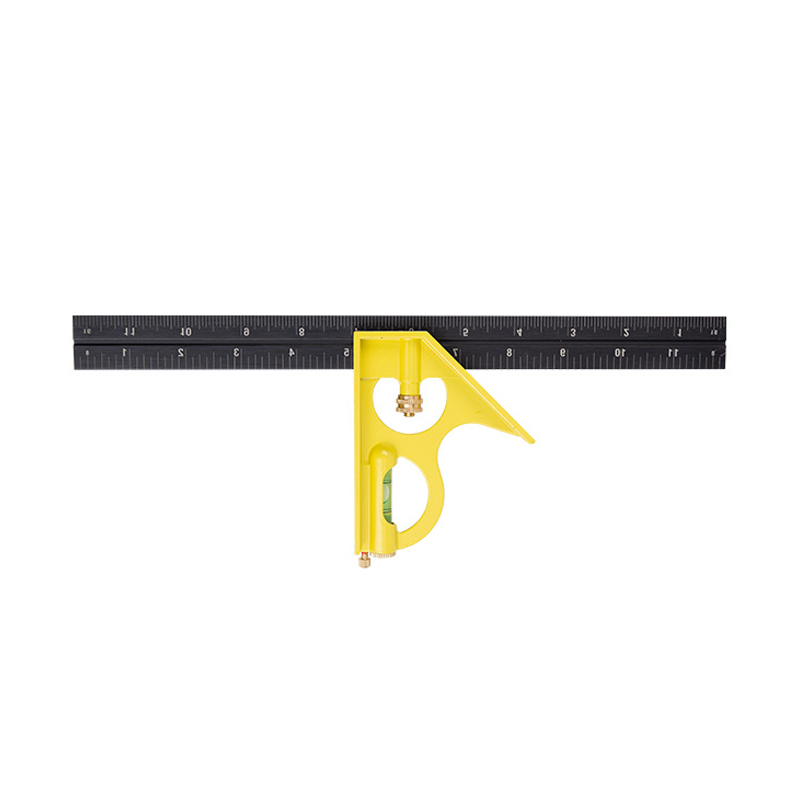

Zinc handle combination square

English

English Español

Español