The scribe that comes with a combination square serves multiple purposes:

1. Marking: The scribe, often featuring a finely tapered and sharp point, is an indispensable tool for precision marking in various trades. Its purpose extends beyond mere superficial marking; rather, it serves as a conduit for translating precise measurements and layout designs onto the workpiece. By utilizing the combination square in conjunction with the scribe, users can ensure that their markings are not only accurate but also clearly defined, facilitating subsequent operations such as cutting, drilling, or assembly. Whether delineating joinery for woodworking projects or marking out intricate patterns for metal fabrication, the scribe's role in achieving accuracy cannot be overstated.

2. Scoring: In applications where accuracy is paramount, such as fine woodworking or metalworking, the ability to create precise scoring lines is invaluable. The scribe's sharp point enables users to score materials with exceptional control and consistency. This process involves applying controlled pressure along the surface of the material, resulting in a shallow groove or line that acts as a visual and tactile guide for subsequent cutting or shaping operations. Whether scoring delicate veneers in woodworking or marking out precise cut lines on sheet metal, the scribe's contribution to achieving clean and accurate results cannot be overlooked.

3. Layout: At the heart of any fabrication or construction project lies the meticulous process of layout and measurement. Here, the scribe emerges as a critical tool for transferring measurements and layout designs from the combination square onto the workpiece with unparalleled precision. By aligning the combination square's ruler or blade to the desired measurement and employing the scribe to make corresponding marks on the workpiece, users can ensure that their layout remains consistent and accurate throughout the project. This precision is essential for tasks ranging from marking out mortise and tenon joints in woodworking to establishing hole locations for hardware installation in metalworking.

To leverage the scribe effectively:

1. Positioning: Begin by securely positioning the combination square against the workpiece, ensuring that it remains stable throughout the marking or scoring process. This minimizes the risk of errors caused by movement or slippage during operation.

2. Steady Pressure: Apply consistent and even pressure while using the scribe to mark or score the material. This helps maintain the integrity of the measurement or layout design and ensures that the resulting markings are crisp and clearly defined.

3. Scoring Technique: When scoring materials, adopt a methodical approach by gently guiding the scribe along the surface of the material. By exerting controlled pressure and maintaining a steady hand, users can create precise scoring lines that serve as reliable guides for subsequent cutting or shaping operations.

4. Marking Precision: For marking tasks, pay close attention to the alignment and placement of the scribe's sharp point on the workpiece. Apply sufficient pressure to leave a discernible mark without damaging the material, ensuring that the marking remains visible and accurate throughout the project's execution.

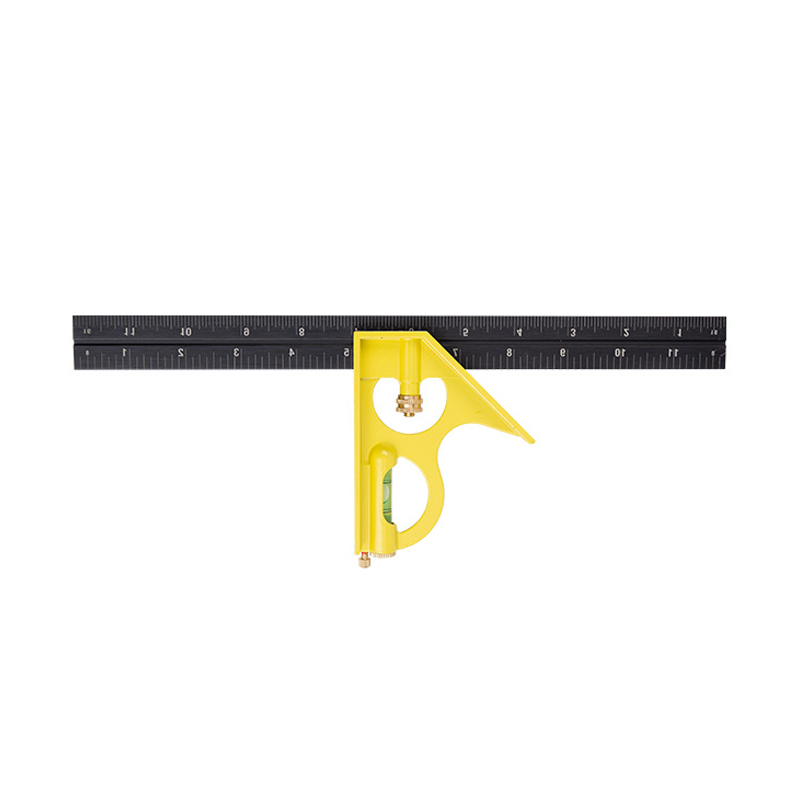

Zinc handle combination square

English

English Español

Español