Proper maintenance and care are crucial for ensuring the longevity and accuracy of a framing square. Here are some guidelines:

Cleaning: Begin by inspecting the framing square for any embedded dirt or debris in the markings and crevices. Use a fine brush, like a toothbrush, to meticulously clean these hard-to-reach areas. If the square has been exposed to particularly dirty or dusty conditions, consider a compressed air duster to dislodge particles before employing a soft cloth for a final wipe-down.

Storage: Store the framing square in a climate-controlled environment to minimize temperature and humidity fluctuations. If stored in a toolbox, add desiccant packs to absorb moisture. For added protection, place the square in a padded case to shield it from potential knocks, scratches, or other inadvertent damage.

Corrosion Prevention: Prioritize the application of a high-quality rust inhibitor. Ensure the square is completely dry before applying the inhibitor, and use a corrosion-resistant oil or wax specifically designed for metal tools. Rotate the square to ensure the inhibitor reaches all surfaces, and consider using a lint-free cloth for an even application.

Avoiding Impact: Regularly inspect the framing square for signs of impact or damage, even microscopic dents or deformities. A magnifying glass can be useful for thorough examinations. If damage is identified, take immediate corrective action, whether it's filing down rough edges or consulting a professional for more extensive repairs.

Calibration Check: Elevate the precision of calibration checks by utilizing a laser level or digital angle finder in addition to traditional methods. Record calibration results in a logbook, noting any adjustments made. This logbook serves as a valuable reference for trends in the square's performance over time.

Protecting the Markings: For enhanced durability of markings, consider using a clear protective coating specifically formulated for metal surfaces. This can act as a barrier against abrasion and fading. In instances where the framing square is subjected to frequent pencil marks, experiment with different pencil hardness to find the optimal combination of legibility and longevity.

Avoiding Excessive Heat: Implement a systematic approach to temperature management by allowing the framing square to equilibrate to the ambient temperature before use. During extreme heat conditions, use reflective covers or store the square in a shaded area to prevent it from becoming excessively hot.

Regular Inspection: Expand the regular inspection to include an assessment of the square's overall structural integrity. Check for any signs of warping or twisting that might compromise accuracy. Engage in a proactive approach by conducting inspections even if the square hasn’t been used for an extended period.

Proper Handling: Introduce comprehensive training on the correct techniques for handling and transporting the framing square, emphasizing the fragility of its edges and the importance of gentle handling. Encourage the use of tool belts or dedicated carrying cases to reduce the likelihood of accidental drops or impacts.

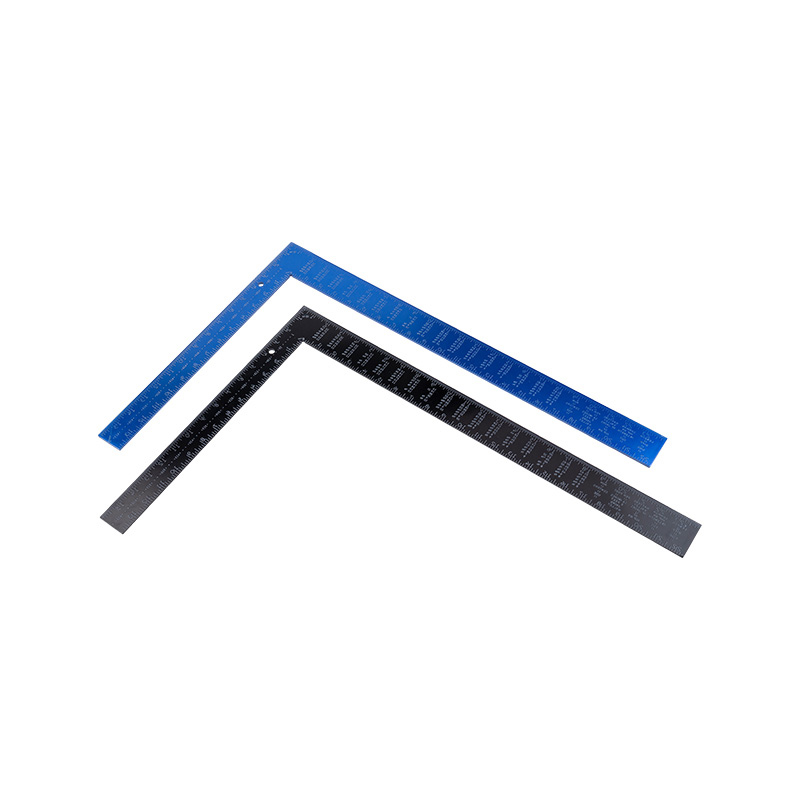

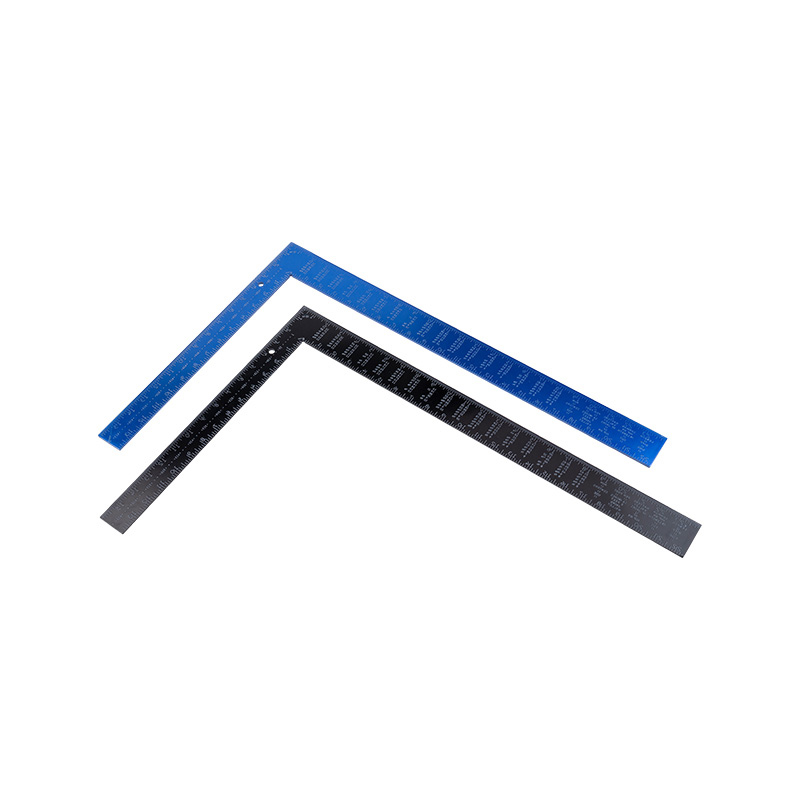

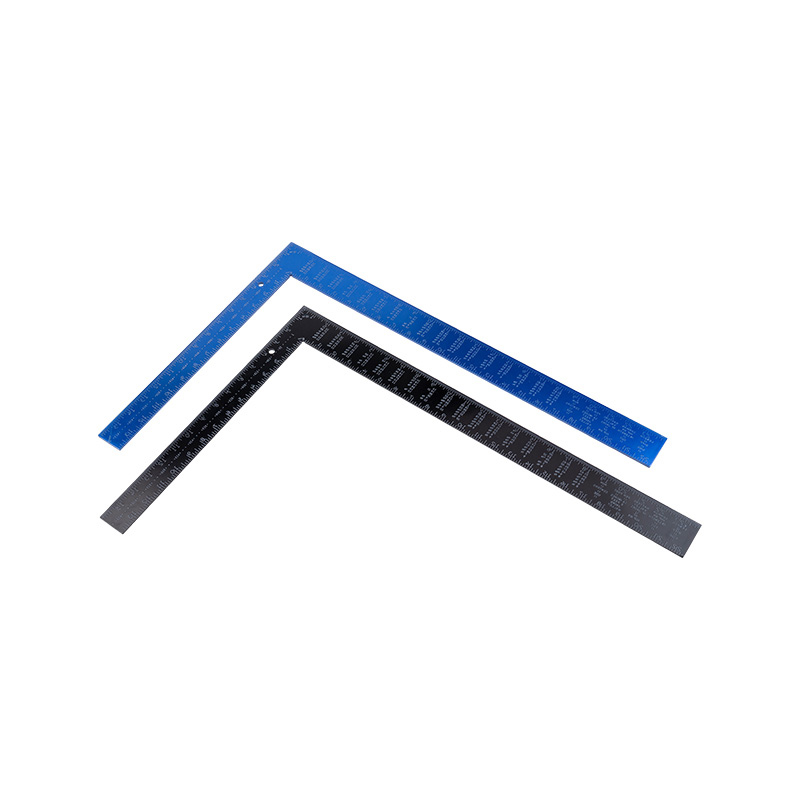

Aluminium framing square